Nest, save & cut jobs

MagicTool is the CAD/CAM nesting software system, designed for automating the CNC programming of sheet metal machines. It provides the most advanced nesting algorithms and strategies for laser, plasma, oxy-fuel, and water jet cutting machines. MagicTool optimizes the results of machines from manufacturers like Lincoln Electric, Amada, Esab, Flow, Koike, Mazak, Messer, Prima Power, Trumpf, Waterjet Corporation and many other.

MagicTool - 3 axis

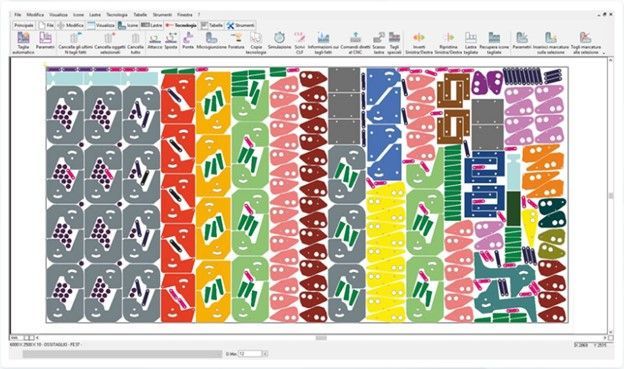

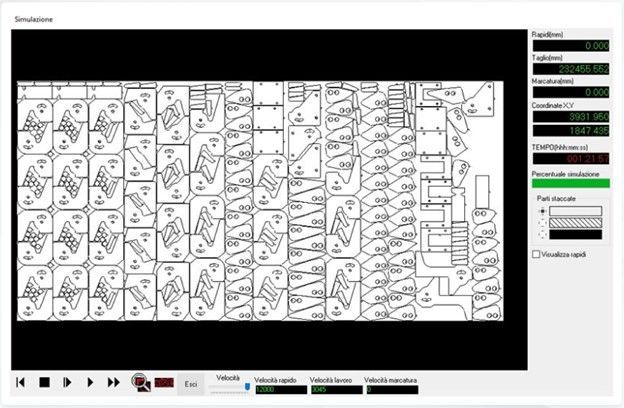

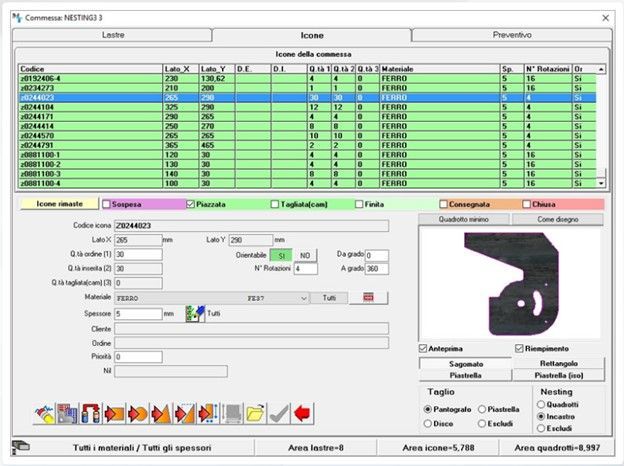

NESTING

This system provides a perfect combination of automatic, semi-automatic, and manual nesting, providing great flexibility and excellent performance. The combination of automatic nesting, along with manual nesting functions like copying, moving, and rotating, proves to be a very powerful tool. MagicTool automatic nesting optimizes part arrangement on the plate for a maximum utilization of parts and remnants. MagicTool automatically detects remnants in the database and allows users to prioritize their use before using a new sheet.

TECHNOLOGIES

MagicTool allows tables to be configured according to material/thickness to define separation between parts and lead-in/lead-outs for different types of contours and dependent on material/thickness and cutting quality. Common cuttings are possible between different parts to limit the pairs of parts with micro-joints and pre-cuts. The system detects any errors in the design and machining in a completely automated way (Logotag).

All MagicTool options are included in a single program. Within the same program environment, the user can: design or import a part, consult the plate database, execute cutting sequences, generate CNC programs, and calculate time and costs.

LASER TECHNOLOGY

MagicTool provides specific laser technology tables for each type of machine. There are various levels of cutting qualities that can be created according to the material/thickness to define: power, speed, frequency, gas, piercing, etc. Other features include reduced entry management, personalized and fast piercing, pre-piercing, pierce reduction, flying cut (pierce “on-the-fly”), micro-joints, corner ramping precision, material and time savings with bridge cutting, common line-cutting, chain cutting, and more.

WATER JET TECHNOLOGY

MagicTool provides water jet technology tables for each machine, speed reduction in corners, special piercing (to detail), and multi-head management, all considering the unique characteristics of cutting with water jet technology. The key benefits include automatic acceleration/deceleration programming, stack cutting capabilities, and an optimal use of consumables through pierce reduction.

OXYCUT/PLASMA TECHNOLOGY

MagicTool supports technological elements such as chamfers, loops and bridges. These technological elements can be assigned manually or automatically according to material and thickness. MagicTool also manages different types of heads/torches and handles any changes between them for optimal cutting conditions.

Other important features include:

- Multi-Torch

- Marking with powder, punch, inkjets, drilling, etc.

- Continous cutting

- Chamfers: revolving and triple torches

- Micro-joints to anchor parts to plate

- Bevels to generate bevelled cut (control of triple and rotary torches) / continuous bevel and five-axis cutting

MagicTool goes beyond the typical plasma cutting software increasing manufacturing efficiency and profitability to a higher level through materials optimization and process efficiency. Key benefits include reducing pierces and saving on consumables, chain, bridge, and common-line cutting to improve production speed and material usage, adjusting self-feed rate and power ramping.

TECHNICAL CHARACTERISTICS

MagicTool is designed to connect to external ERPs.

Other features of MagicTool are:

- Teamwork - the system can work autonomously or be installed as a part of a network. By using the floating license option, multiple users access the system.

- Time and True Cost Calculations - MagicTool manages all the technology of the machine and calculates time and cost by piece and by sheet.

- Parametrics Parts Library - The MagicTool has a wide library of parametric parts, available in the Logotag.

- Open Database - The MagicTool database is open and enables the user to access it to find parts, manufacturing orders, plates, etc. by using criteria such as material, thickness, client, date, etc.

- 2D Design - Logotag is a highly efficient 2D CAD module especially created to design 2D plate parts. It includes functions for the automatic detection and correction on unclosed contours, shape recognition, geometry validation, and true-type font support.

- Import/Export Intelligent - MagicTool may be linked to the major CAD systems on the market (DXF, DWG, DSTV, etc.) and may also use graphic files (JPEG, BMP, TIF, GIF, etc.).

Magic Tool

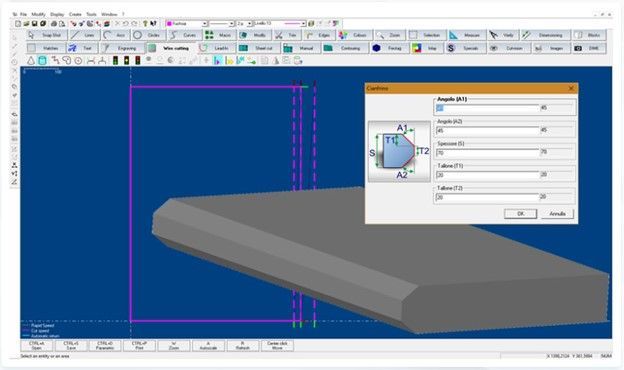

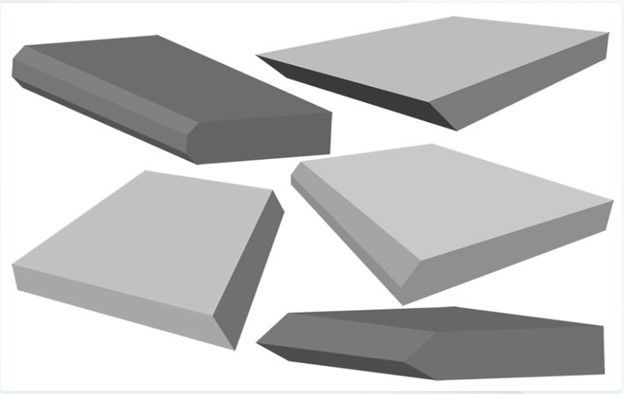

5 axis (Bevel)

The CAD CAM software module for bevel cutting. It represents straight cuts, cylindrical holes, exact bevel angles and parts with absolute dimensional accuracy. The application is also characterized by enormous flexibility. Almost all possible technology parameters and operation details can be adjusted. Bevel cutting commonly refers to the cutting of a part with an edge in such a way that the edge is angled in relation to the surface of the part. It is done to allow a greater surface area on the edge for welding preparation and other final assembly methods.

To achieve quality bevel cuts the NC code generated must match exactly the capabilities and performance of the machine used. Lateral and angular offsets must be considered for all cuts. Lead-ins and lead-outs as well as joining macros between individual contour areas must be placed in such a way that no damage to the contours occurs. Bevel cuts make the highest demands on the programming of the cutting plan.

Benefits:

- Full control of your Oxyfuel, Plasma or Laser cutting is dramatically simplified

- Bevels are accurate - guaranteed

- Shorten production time

- Increase quality and productivity for bevel cutting

- Analyses the contours and provides suitable, customizable technologies for optimal cutting

- Implements the optimal parameters to ensure the highest quality cutting

- Customer optimizable databases are supplied for many types of cutting processes

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

Contact

Email info:

info@taglio.it

Email Sales: sales@taglio.it

Email Support: support@taglio.it

Tel:

+39 0173 619877

Subscribe to our newsletter

newsletter

We will get back to you as soon as possible.

Please try again later.

Taglio S.r.l. | P.IVA - Cod. Fisc. - R.I.: 01832840043 | Via Roma, 12/A - Piobesi d’Alba (CN) – Italia | Tel: +39 0173 619877 - Fax: +39 0173619879 |

Privacy policy -

Cookie policy

-

Cookies banner

- Website created by

etinet.it